Flexible floor coverings, technical materials (fibreglass, tarpaulins, coated sheet, etc.), packaging/wrapping rolls, etc.

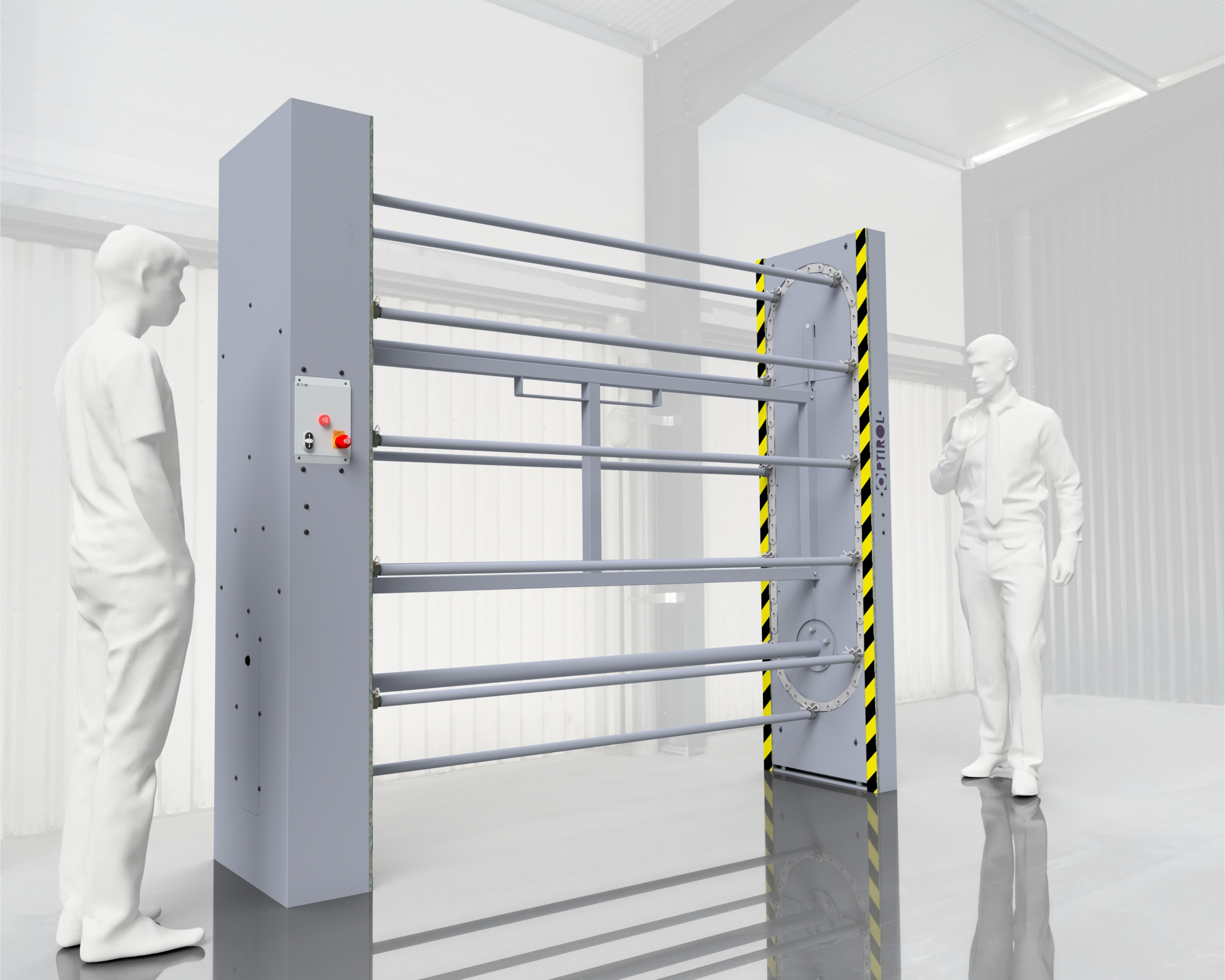

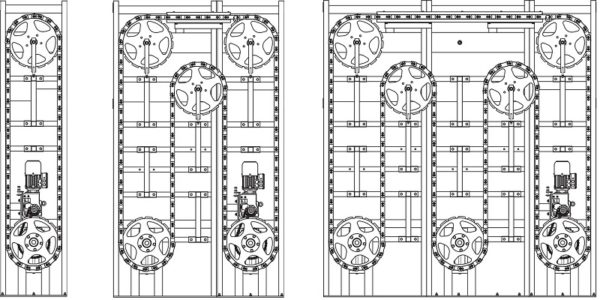

On the correct axle for your roll or bobbin’s inner diameter – use the load calculation to determine the right axle diameter to prevent flexion. The material may be pulled from the roll mounted on the carousel by a fabric cutting or inspection machine or simply onto a table for end-cutting and quilting. The axle position is adjustable on the drive chain, providing great flexibility for stock optimisation. Available in one loop and multiloop versions, depending on the total cumulative load.

Centring cones – Flange guide – Roller axle – Securing straps – Label holder – Regulator for start/end of cycle (depending on overall load) – Cell rail – Dual forwards/backwards control – Manual or automatic cutting table – Measuring system – Unrolling cradle – Pay-out reel on wheels, such as a crank cylinder – etc.

With a dedicated load handling truck for ergonomic loading on the lower section; several truck types are available, including battery-powered load handling trucks.

13 heights available.

5 ranges available depending on maximum diameter. 3 types of drive chain.

Max. weight : 1000 kg.

Max. diameter : 980 mm.

Total length : 2 to 6.5 metres

Linear speed : 4 to 6.10 m/min. maximum.

Control : press and hold or automated.

Power supply : 220 V or 380 V – 0.55 kW to 1.5 kW

Outer diameter of roll – Inner diameter of roll – Maximum width – Maximum weight – Quantity for storage – Single- or double-sided use – Heights available – Supply of a manual or automatic cutting table – Press and hold or automated control – Other possible restrictions (ATEX zone, power supply system, etc.)

Easy to use

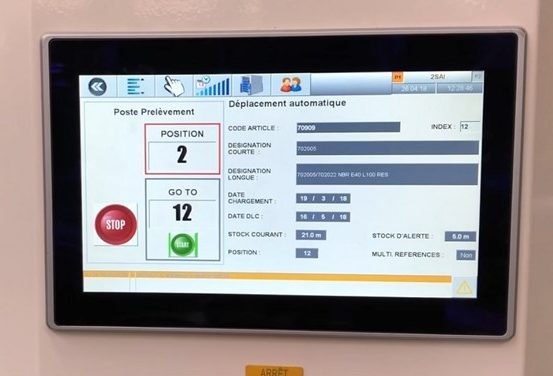

The default control method is pressing and holding the button to reach the desired item. The carousel can be rotated in both directions.

Safe to operate

No risk for your employees, with an ergonomic work height when loading and unloading

Quick access

Press and hold the button or enter the location code to quickly reach the right item

Optimised space

Easily make use of your building’s overhead space

Stock management

Makes stocktaking faster – can be integrated with ERP and WMS for optimised management.

Heavy and bulky product storage

Specific products for every application

Forward or Reverse press button

Control with tactil screen